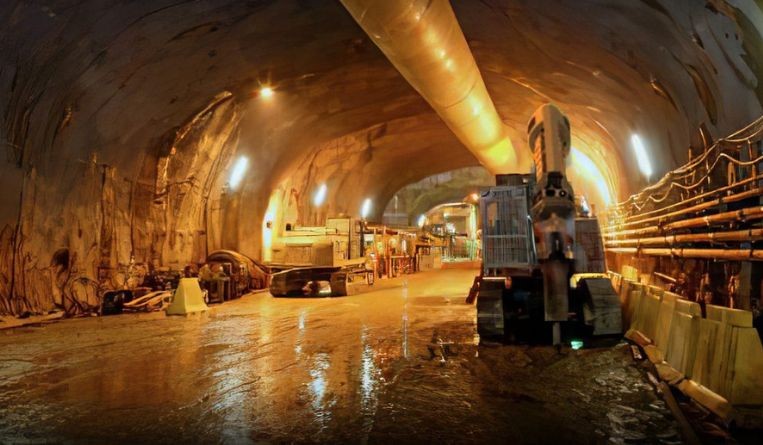

EXAMINING PATENTS IN THE MINING INDUSTRY

30 November 2022

Climate change is resulting in companies and consumers alike driving increasing use of green technology. Industries that are vital to the lives of people worldwide are incorporating such technologies, including the mining industry.

While a 2019 report by the World Intellectual Property Organization, Measuring Innovation in the Mining Industry with Patents, calls the mining industry traditionally “a slow innovator”, the same report notes that since the 2000s – and particularly since China’s appearance on the global mining scene – “mining innovation has started to increase rapidly after periods of stagnation and downward trends,” as has its reliance on the legal system to protect that innovation.

But there is still a serious need for greater research into the economic and policy elements that encourage the mining industry to become more sustainable. In fact, researchers scrutinized the trends in global patent applications from the minerals and mining sector to come up with methods for promoting R&D in mining-related climate change mitigation technology, or CCMT.

These researchers discovered that changes in raw metal prices and the Paris Agreement both had an impact on the industry’s development of CCMTs, but to varying degrees depending on the nation and the sector’s economic contribution.

“Traditionally, the mining industry has not developed as fast as other industries, like pharmaceuticals, for instance,” says Panisa Suwanmatajarn, a managing partner at The Legal Co. in Bangkok. “However, global warming is one of the top issues the world is facing. Any technologies that can tackle the issue will receive global attention. Those patents will play a significant role that comes along with the technological developments as the inventor will need exclusivity over its invention in the mining industry.”

She says that given these new technologies in the mining industry, companies that are involved in inventing new technologies need to learn how to protect their inventions through the patent system.

“[An entity] could lose its novelty and of course valuable inventions if it is careless and discloses such invention to the public,” she says. “[It must also] seek protection in multiple jurisdictions as most inventions are valuable anywhere in the world. Companies with new technologies need to consult with an expert in the patent field.”

Jonathan Chu, a partner at Lau, Horton & Wise in Hong Kong, agrees. He says that it should be a priority for companies to ensure that they are diligent and efficient when assessing their technology for IP protection.

“This ultimately relies on the operations of the company and its ability to quickly identify the existence of and commercial value of their inventions,” he says. “This may be as simple as having processes in place or personnel to focus on this. The last thing a company would want is for a competitor to beat them to acquiring a patent for similar technology. As a part of the process, it is also important to ensure that the inventions belong to the company, this may mean having the correct contracts in place whether for third-party inventors or employee inventors. Further, not all inventions should be patented or qualify for patenting, and is, instead, valuable know-how; companies should ensure that all confidential information is handled correctly and kept secure.”

He adds: “Finally, like businesses in other industries, once they have identified an invention worthwhile to patent, companies should work out a strategy for their patent filing to ensure that they have protection in the relevant jurisdictions and that the filing process is cost-efficient.”

Tax relief and tax rates

With some jurisdictions conferring enhanced tax relief on expenditures incurred on the creation of IP and/or lower corporate income tax rates in respect of certain IP-derived income, care should be taken to ensure that these are properly addressed, especially if the company is new to IP transactions.

“Companies should be mindful of the tax regime in their relevant jurisdictions and how there can be such benefits,” says Chu. “For example, in Hong Kong, there is an R&D tax deduction regime which allows for certain R&D expenditures to qualify for a tax deduction.”

He adds: “We regularly work with tax advisors as well as our firm’s tax team on the legal side in relation to issues such as transfer pricing and structuring a company in a way that makes it as tax efficient as possible. I would recommend that companies speak with their tax advisors to ensure that they are set up and operating in a way where, if available, they can make use of such relief.”

“There are a number of factors driving innovation in the sector,” he says. “These factors will certainly give owners of the technology a competitive advantage. For example, with mining technology moving increasingly towards digitalization, inventions in the AI, VR, AR, and sensor spaces, for example, would contribute to greater efficiency in mining, which will certainly provide a competitive advantage. Such technology may also be licensed, allowing technology owners to make revenue from the industry without having to do any mining themselves.”

In India, the government has floated several tax incentives to promote innovation in various industry sectors:

-

Export-oriented units: 100% export-oriented units are exempted from payment of duties and taxes.

-

Free trade zones: The income tax act provides tax benefits to newly established undertakings in free trade zones.

-

Support for International Patent Protection in Electronics & Information Technology (SIP-EIT): This is a scheme to provide financial support to MSMEs and technology start-up units for international patent filings. Further, it is designed to encourage innovation and recognize the value and capabilities of global IP and capture growth opportunities in the ICTE sector.

“In India, startups incorporated on or after April 1, 2016, can apply for income tax exemption,” says Rachna Bakhru, a partner at RNA, Technology and IP Attorneys in Gurugram. “Recognized startups that are granted an Inter-Ministerial Board Certificate are exempted from income tax for a period of three consecutive years out of 10 years since incorporation.”

She adds: “The investment decision and setting up a new company should be thought through to consider royalty payments, licensing fees on technology transfer and taxes. The payment of royalties between group companies may be subject to transfer pricing and attract withholding tax. Care should be taken when setting royalties to avoid transfer pricing adjustments. Where a company is to be established to hold group IP, to manage withholding tax, consideration should be given to jurisdictions which benefit from a wide double tax treaty network. When establishing such a company, care should also be taken when transferring IP created by other group companies to the IP holding company, as any such transfer will have tax implications, possibly in more than one jurisdiction.”

Other risks and challenges in the mining industry

Bakhru says that India follows patentability standards (novelty, inventive step and industrial applicability) set by the World Intellectual Property Organization, and that there are no specific exclusions in the Indian patent act to restrict the patentability of inventions from the mining industry.

“In general, Section 3 of the Indian Patent Act outlines inventions that are not patentable,” she says. “Out of these, Section 3(f) is applicable to the mechanical, electrical and electronic inventions, and an invention claiming a mere re-assembly of known devices in which each device will act independently is not eligible for being patentable.”

She adds: “Overall, in view of Section 3, in India, the benchmark for novelty and inventive step is high in general. Further, India does not have laws to protect incremental innovations such as utility patents. Therefore, companies find it challenging to protect inventions that do not qualify the criterion for patent registration, although the said innovation is of commercial significance to the company’s business.”

Kar Liang Soh, managing director at Ella Cheong in Singapore, says, “I think our biggest challenge in Singapore is the lack of natural resources to extract. Be that as it may, there are several mining companies with operations in neighbouring countries such as Indonesia that are headquartered in Singapore. The absence of a mining industry may make filing mining-related patents in Singapore seem counterintuitive. However, mining companies with a presence in Singapore are well positioned to reap the benefits of a mining-related Singapore application that are realized primarily by Singapore’s ability to accelerate examination of commercially valuable patent applications in mineral-rich ASEAN countries.”

He adds: “Companies that first file patent applications in Singapore can potentially get a patent granted in as little as six to nine months from the filing date via the Singapore Patent Fast Track programme. In contrast, it typically takes at least four to five years to get a patent granted in neighbouring mineral rich Indonesia.”

Once granted, the positive results of the Singapore patent can be used to accelerate examination of a corresponding patent application elsewhere in ASEAN via the ASEAN Patent Examination Co-operation (ASPEC) Programme. Once an ASPEC request is made, an Industry 4.0 patent application can enjoy a quick turnaround time to receive a first office action in six months in the country in which the request was made.

Changes in the future

Although the mining sector has not traditionally relied heavily on IP, this may change in the near future, as technology provides both a competitive advantage and a potentially lucrative revenue stream. With this, Soh says that decarbonization is necessary to meet net-zero emissions goals and presents both new opportunities and challenges for the mining industry.

“To meet demand for battery products that are vital for the transition to a net-zero emissions world, it is estimated that 384 new mines – graphite, lithium, nickel and cobalt – will be required by 2035,” he says. “The mining industry is not exempted from decarbonization and will likewise face pressure from governments and investors to reduce emissions in the near future. Indirect pressure can also be expected from society at large as exemplified by the surging demand of consumers who are willing to pay a premium for low emissions products. It was previously unclear if a genuine return on investment could be realized from going green. However, the five-fold to eight-fold increase in energy costs in Europe in the past two years is further impetus to go green.”

Further, and of more immediate concern for the mining industry is a 35% drop in global mining productivity between 2004 and 2012 as evinced by the MineLens Productivity Index. While it has since begun to recover, the recovery is weak, and the index remains over 30% below the levels attained before 2004. Possible reasons for this decline remain a subject of debate and have ranged from the ever-present threat of depletion of deposits to the notion that mining productivity is cyclical and dependent on economic factors. For example, if prices are high, productivity takes a backseat as companies focus on volume. Conversely, when prices are low, cost-saving measures tend to come to the forefront.

“The fourth industrial revolution where Big Data, the internet of things and 3D printing are buzzwords presents an opportunity to use technology to increase productivity with potentially revolutionary results,” Soh said.

Soh notes that data collection and analytics may well have the largest impact on the way the mining industry operates. Massive amounts of data obtained from a vast network of sensors and the ease at which these data can be communicated and consolidated into datasets has already started to revolutionize the mining industry. The analysis of these datasets using powerful tools that utilize machine learning and cutting-edge statistical techniques can lead to real-time insights into every conceivable aspect of the mining process from exploration to processing.

“Significant increases in efficiency throughout the industry are already being realized,” he says. “For example, the use of sensors and machine learning can help to predict the actual lifespan of specific parts and allow them to be safely used for longer intervals between changes as opposed to a traditional time-based approach, thus allowing parts to be used to be safely used for longer and realizing significant cost savings.”

He adds: “The insights gleaned from the analysis of relevant datasets can be used to inform decision-makers on bottlenecks in the process to better direct the deployment of existing technologies such as automation and robotics at bottlenecks.”

The application of technology as illustrated above to solve mining-specific problems can lead to the creation of non-obvious solutions that can potentially be protected in the form of patents, he says. “Patentable solutions include not just solutions related to mining processes but also equipment and systems applied to mining. Innovative solutions that can allow the mining industry to improve productivity while bringing down costs may be of the most commercial benefit and can be exploited through patents. Ideally, these solutions will simultaneously reduce the environmental impact of farming.”

He adds: “Given the low volume of patent applications filed in relation to mining in the last decade, first movers that have secured legal monopolies by way of patents can stand to reap the rewards both operationally and financially. An upsurge in mining-related patents may be expected as major players begin to employ technology in their bid to stay competitive.”

- Excel V. Dyquiangco